In my time, it has often been said that the influence and power of the architect has been diminishing, but I’ve honestly not found that to be the case. Technology and roles have changed, but the desire to create great architecture is as strong as ever and that flows through to product placement within architecture. If bad products are placed in a great building, it diminishes the architecture. While an architect may experience constraints on time and budget, which restricts their complete freedom in designing the products and fixings within a building, at least the architect can make a choice based on a range of materials and finishes, helping to keep their sensibilities alive and creating something with integrity.

When I was in practice as an architect I was fascinated by how, having met a variety of suppliers, some of them intrinsically knew what my motivators and interests were, as a designer, a real instinct for understanding my design culture and ethos.

One of those suppliers was d line – a Danish company with a pedigree for creating classic, architectural hardware. Elementer (d line’s distributor), worked extremely closely with architects with many of its personnel being from the architectural community and that fascinated me.

It was perhaps serendipitous that many years later I worked for d line, developing products with Knud Holscher and selling those products to architects. In 1999, I created a separate entity in the UK, now trading as dlinexsign ltd, with a focus on developing sign systems, with xSign being our primary brand. Just like d line our culture is all about aligning ourselves with the architectural community and contractors to develop products that they really want. Today, we design, manufacture and install a range of sign systems to internal and external facades across the UK and the world.

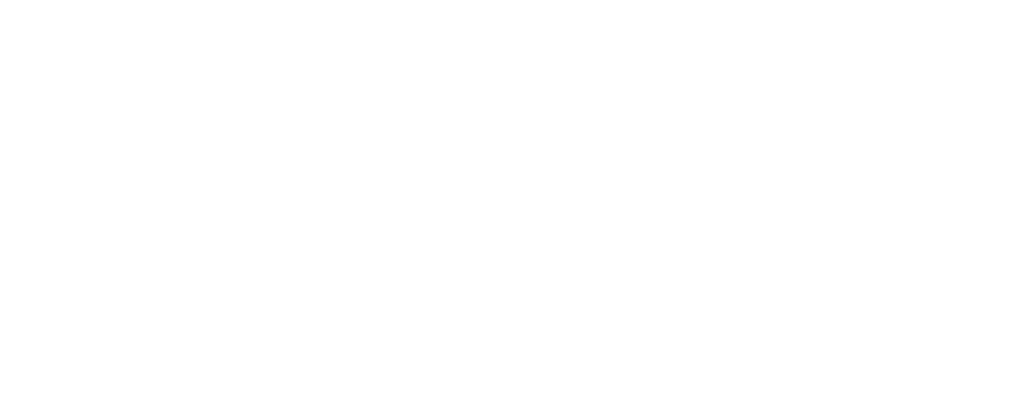

Our strong design and construction links have helped us develop pre-engineered and modular fixing systems in recognition that signs need to be changed easily and quickly and flexibly, with a varied palette of materials. Interior material choices have previously been limited because they have been made of extrusions – you could have anything as long as it was painted aluminium! Whereas, if you look at the materials in interiors of modern architecture, you’ll see leather, Corian, stainless steel, stone, bronze. So, why not make signs with those materials and give our specifiers complete freedom of choice?

Traditionally the challenge for architects and contractors has been the time constraints to prototype products in a short project window and the risks of creating something that hasn’t been done before. That’s where pre-engineered fixing systems can be effective, because we can apply it to any material. And that’s where our tagline “design freedom through engineering” comes from.

Ultimately every project brings unique challenges. Internally, we often talk about trying to offer something to all decision makers. The decision-makers vary from project to project from the architect to the project manager to the brand manager. It’s important that our team and approach are sensitive to all project players and our heavy investment in technology helps so that we can offer a great range of choice to all stakeholders.

In progressing and innovating our range of products and sign systems, we prolong a vision of aligning with an architectural culture that has existed before us through Franklin-Wright, Bauhaus, Arne Jacobsen and Knud Holscher. At least, that is our hope and wish.